Making Planters Out Of 3D Printed Molds

One of the more practical uses for 3D printing is to create molds to cast items out of different materials. You can print out a plastic object but sometimes it's preferable to have the final object be a nicer material. I’ve been experimenting with casting some planters out of plaster and concrete.

Traditionally to make a mold you create a prototype of the final object and then use silicone to make a mold of it. 3D printing now allows you to print the mold without making an original copy of the object.

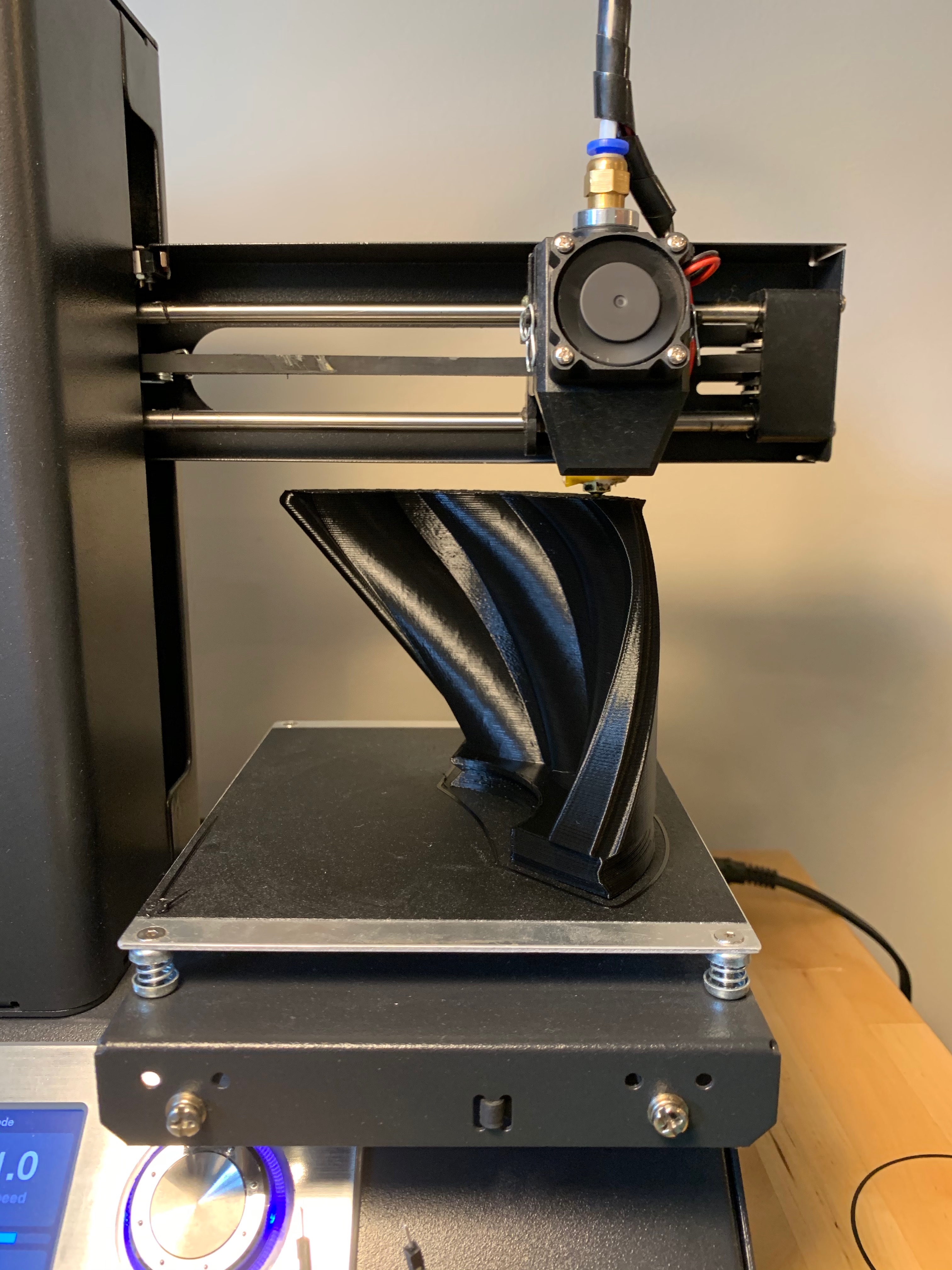

I decided to try printing two different molds I found designs for online. One by Alexandre Chappel and another by Espartaco Degano. The prints took over 20 hours to complete but they can be used many times. You could get this time down a bit by printing with a lower resolution. I printed mine in fairly high quality so the final objects would come out as smooth as possible. Sanding the plastic (PLA) molds is very difficult so you're better of sanding the planter itself.

Once the first molds were ready I decided to try casting the first few planters out of plaster. It seemed a bit easier to use, sets faster and would be less likely to damage the molds. My first attempts had some mixed results. The larger mold worked well but there were quite a few bubbles. The smaller mold leaked a bunch and didn’t work well at first. For the second attempt I decided to cover all the seams with hot glue. This turned out to be ideal and kept the mold sealed but was easy to peal off at the end. Mixing the plaster a bit thinner also allowed it to pour better. Tapping the sides of the mold after pouring helps get rid of the bubbles. To make the planters a bit more unique you can mix acrylic paints into the plaster.

After making a bunch of plaster planters I gave concrete a try. It’s worth noting you don’t actually want concrete but instead a cement mix. This is because concrete mixes contain aggregate (rocks) that get in the way for small molds. I bought fast setting concrete hoping the aggregate would be small enough to not cause any problems. Mixing the concrete by hand and filling the molds was very difficult. Not wanting to waste the bag of concrete though I went back to my 3D printer for a solution.

I modeled quick screen in Fusion and printed it. This allowed me to scoop the concrete and pour it through the screen to filter out all the larger rocks. Without the aggregate the fast setting concrete worked really well. It’s much easier to mix and pours well into the molds.

![]()

The last thing I wanted to try was to compare these 3D printed molds to some silicone molds. I picked up a basic set of silicone molds from Amazon and gave them a try. It turns out these work a lot better. If you’re just looking for a quick way to make some planters this is without a doubt the best way to go. They’re much easier to clean and they leave the piece with incredibly smooth sides.

Although the silicone molds are better in a lot of ways I still think 3D printed molds are worth making. It’s a fun project and it’s a great way to experiment with different materials.

If you found this post useful consider buying me a coffee:

Related Posts

Experimenting With Low Cost 3D Printing Custom 3D Printed MIDI Controller Knobs